Hi, Readers.

The public preview for Dynamics 365 Business Central 2024 release wave 1 (BC24) is available. Learn more: Link.

I will continue to test and share some new features that I hope will be helpful.

Business value:

https://learn.microsoft.com/en-us/dynamics365/release-plan/2024wave1/smb/dynamics365-business-central/assemble-project?wt.mc_id=DX-MVP-5004336

Assemble to project helps you improve inventory management by assembling to order only when it’s required, and enable other ways to customize projects.

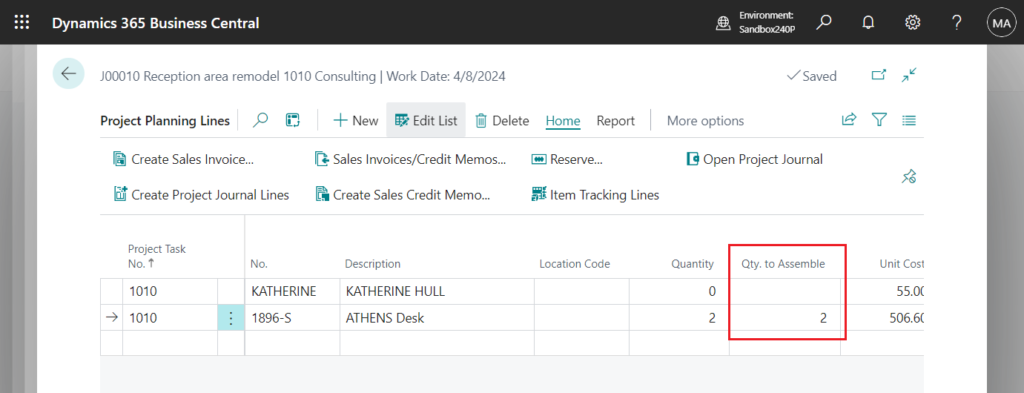

With this wave (BC24), we can create Assembly Order directly in the project planning line.👏👏👏

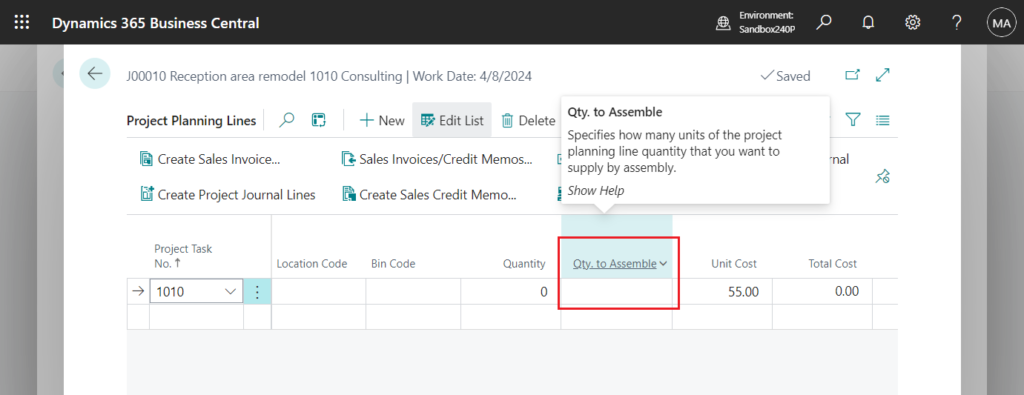

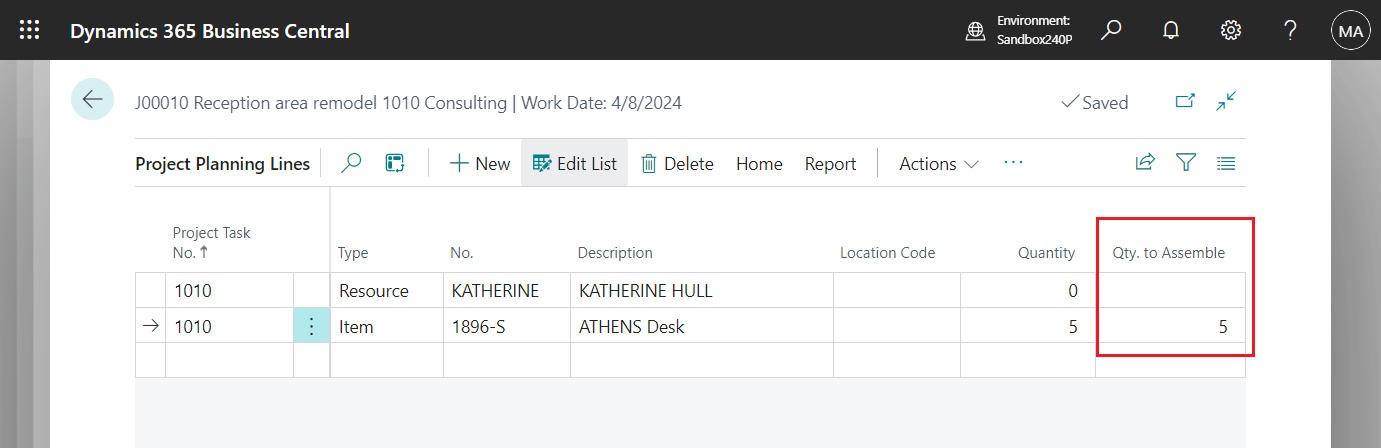

Qty. to Assemble

Specifies how many units of the project planning line quantity that you want to supply by assembly.

Let’s see more details.

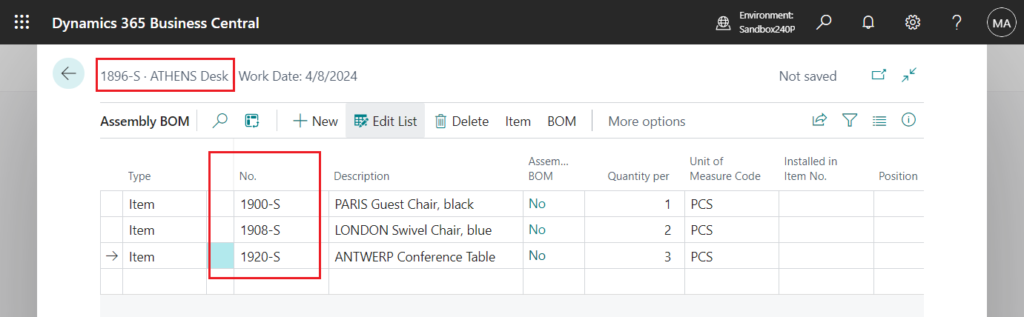

Assembly BOM:

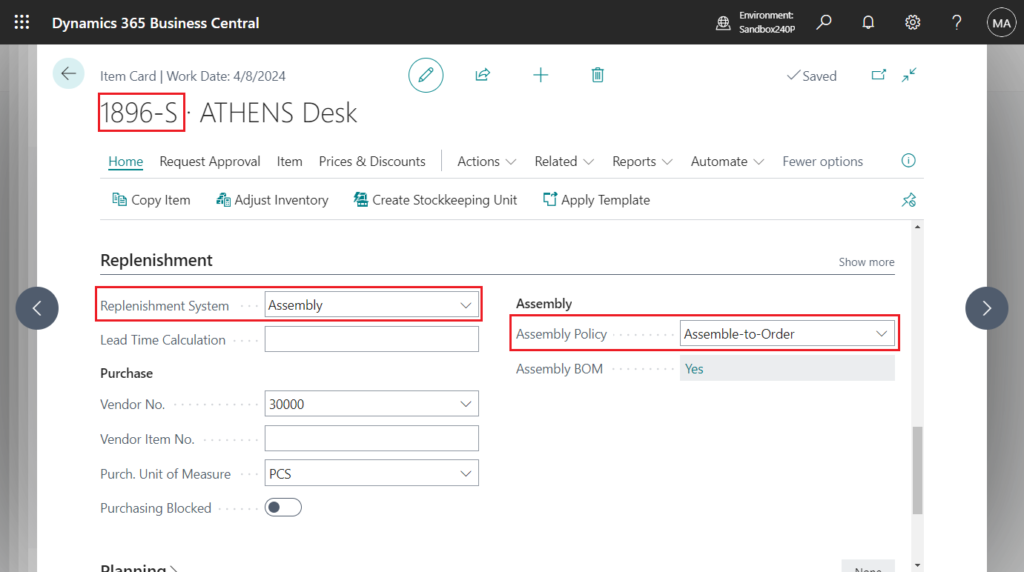

Replenishment System = Assembly, Assembly Policy = Assemble- to-Order on the Item Card.

When you enter an assemble-to-order item on a project planning line, an assembly order (Assembly Quote???) is automatically created. The assembly order is based on the project planning line, and its lines are based on the item’s assembly BOM.

Test video:

PS: This is the same as on the sales order line.

Items that are set up for assemble-to-order aren’t expected to be in inventory and will be assembled when it’s included on a sales order. An item is set up for assemble-to-order when the Assembly Policy field on the item card contains Assemble-to-Order. When you enter the item on a sales order line, an assembly order is automatically created and linked to the sales order.

More details: Assembly Management (Kitting) without the need of manufacturing functionality

Assemble to project supports the following warehouse configurations:

- No warehouse handling: Use a project journal to post full or partial usage. The output and consumption of components post automatically for the assembly order.

- Inventory pick: Use an inventory pick to post full or partial usage. The output and consumption of components post automatically for the assembly order.

- Warehouse pick: Create and register warehouse picks for components, and then use a project journal to post usage. Business Central verifies whether the consumed assembly components were picked. The output and consumption of components post automatically for the assemble order.

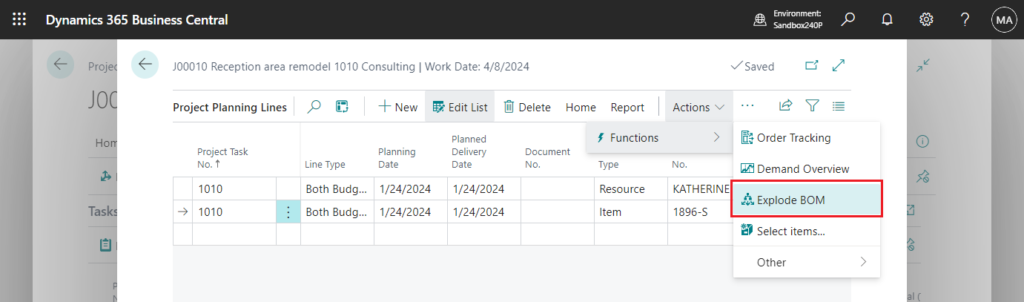

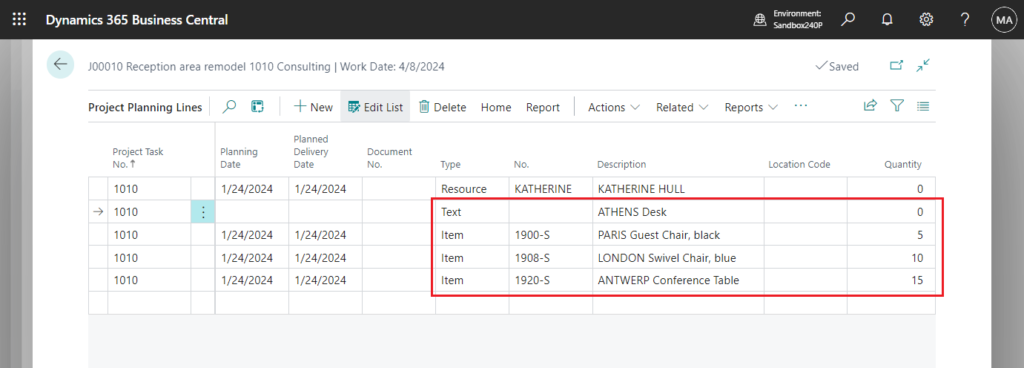

You can also use the Explode BOM action in the Project Planning Lines to convert the product into a set of components.

The following are known limitations:

- The Quantity to Assemble to Order field isn’t available for closed projects.

- For warehouse pick scenarios, the Quantity to Assemble to Order can be either zero or equal to the quantity. You can’t mix assemble to order and assemble to stock on a project planning line. You must create separate project planning lines.

- Assemble to order does not affect billable parts of a project. An assembly is included on sales invoices, but not its components. You can’t edit the Quantity to Assemble to Order field for Billable lines (not Budget+Billable).

- Order planning and the planning worksheet aren’t affected because the job is the input for planning. The planning engine considers the assembly as demand.

- You can’t enter a negative quantity in the Quantity to Assemble to Order field.

- You can’t undo an assembly.

Great. Give it a try!!!😁

END

Hope this will help.

Thanks for reading.

ZHU

コメント