Hi, Readers.

The public preview for Dynamics 365 Business Central 2023 release wave 1 (BC22) is available. Learn more: Link.

I will continue to test and share some new features that I hope will be helpful.

Use advanced warehouse functionality with minimal complexity:

Business value:

You can use several features that were previously available only for locations that use directed put-away and pick, which added advanced processes, without adding unneeded complexity.Feature details:

While the complete set of warehouse features has been available in the Essential license for a long time, to use it you needed to enable directed put-away and pick for selected locations. Enabling directed put-away and picks makes advanced warehouse processes available, which might add more complexity than the business needed. In this release, we’re making various features available:

https://learn.microsoft.com/en-us/dynamics365/release-plan/2023wave1/smb/dynamics365-business-central/use-advanced-warehouse-functionality-minimal-complexity

- Zones

- Movement worksheet

- Calculate Bin Replenishment task

- Bin Capacity Policy

- Warehouse class check

- Special equipment in warehouse documents

Some features are available in previous versions, let’s see more details.

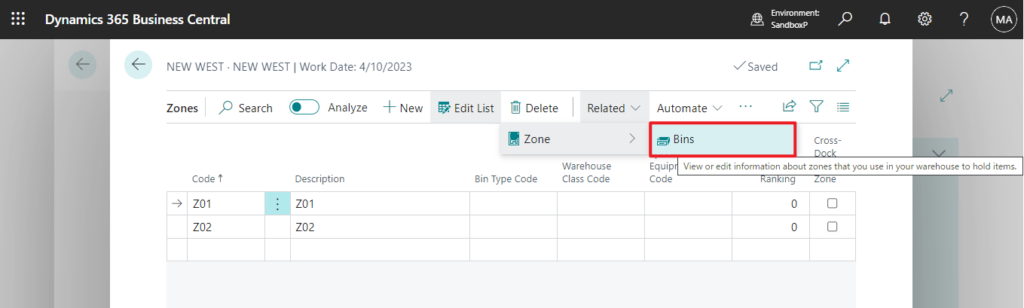

Zones

In warehousing, bins can be grouped in zones. Each zone can consist of one or more bins. Most properties assigned to a zone will be assigned by default to bins that are created for the zone.

Bins

View or edit information about zones that you use in your warehouse to hold items.

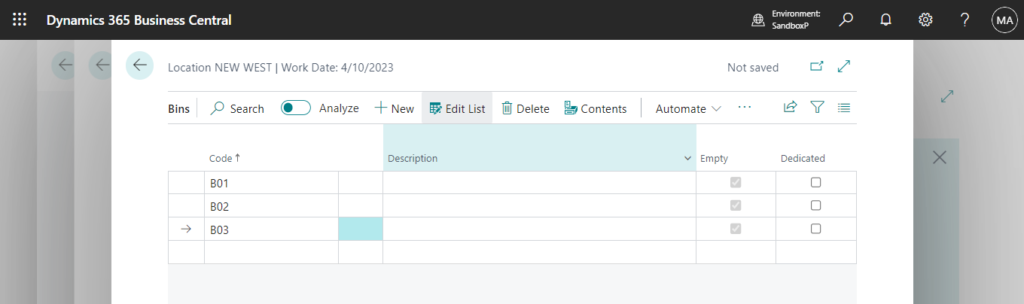

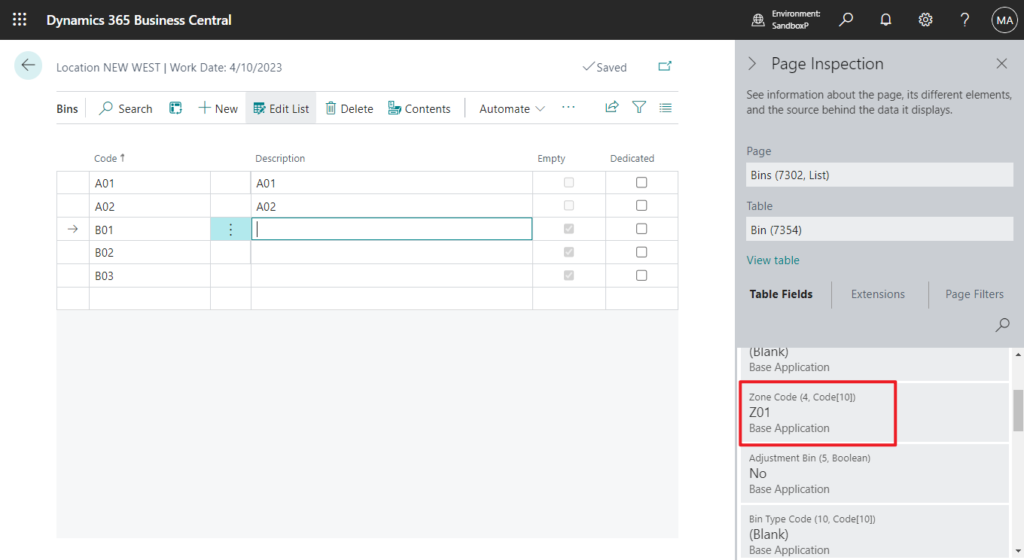

Then we can add Bins in the Zone, and the added Bins will be automatically associated with the Zone Code.

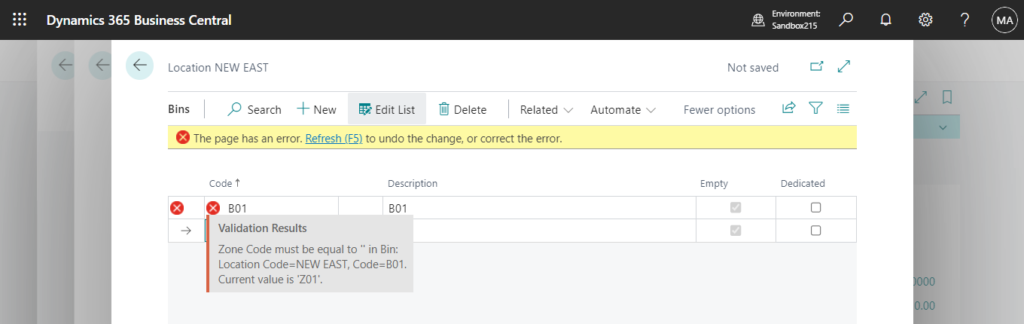

PS: In BC 21.5

Zone Code must be equal to ” in Bin: Location Code=NEW EAST, Code=B01. Current value is ‘Z01’.

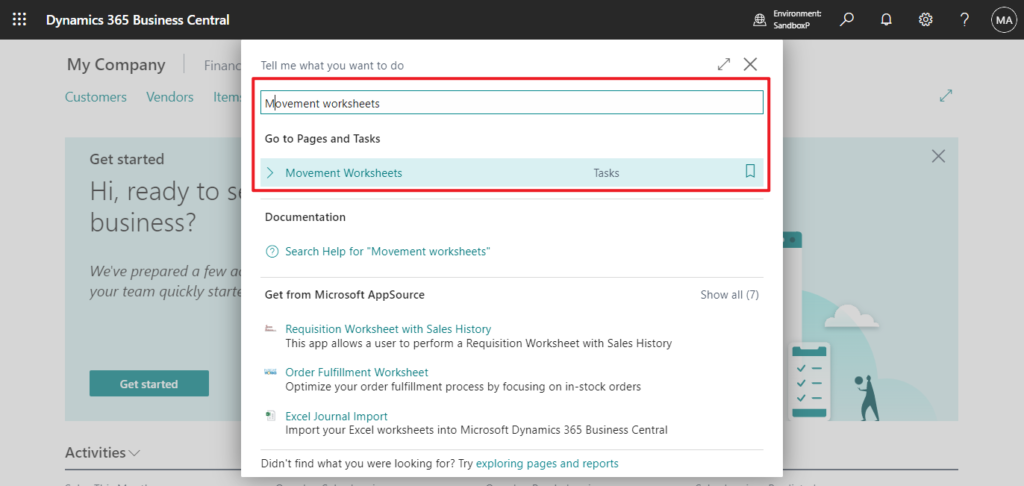

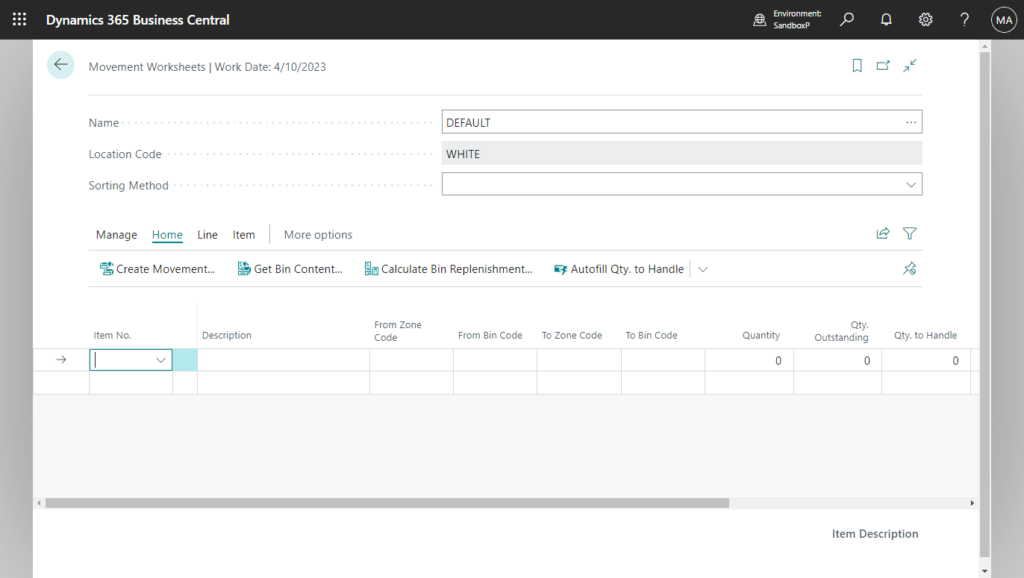

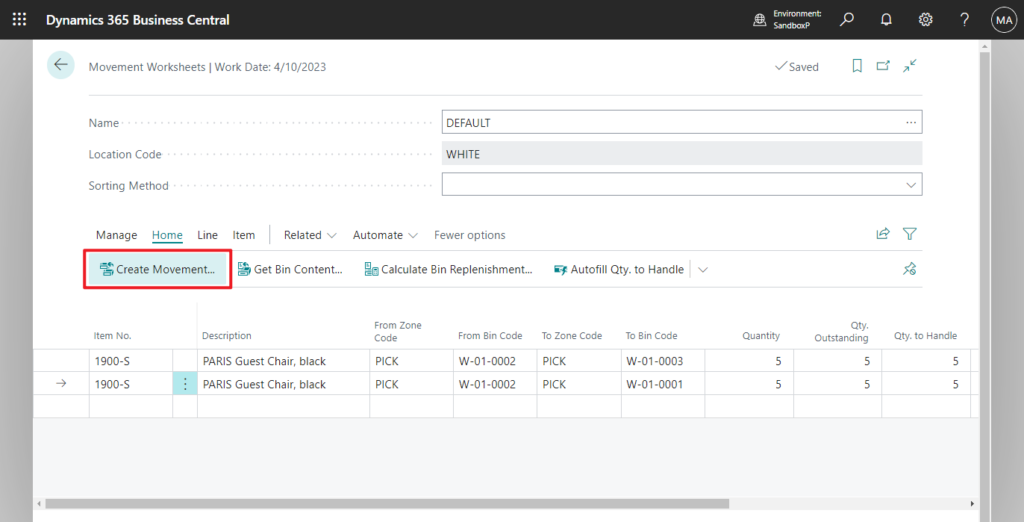

Movement worksheet

Use movement worksheets to plan movements of inventory in your warehouse.

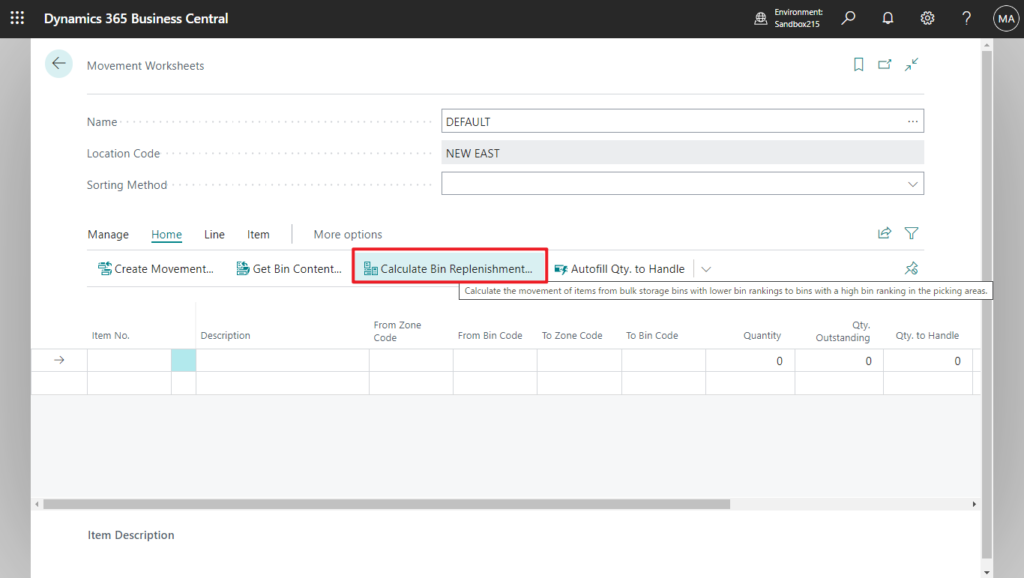

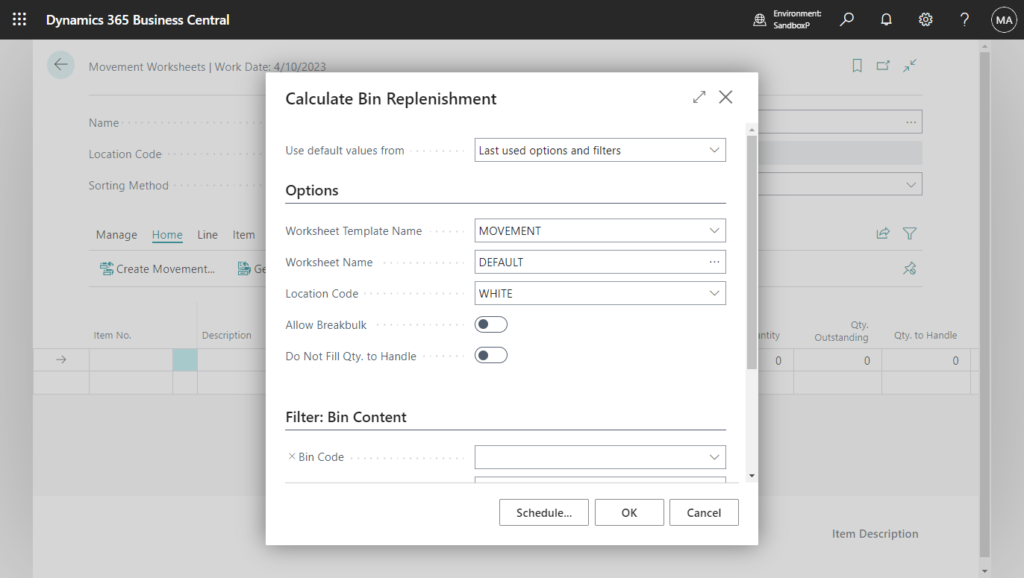

Calculate Bin Replenishment task

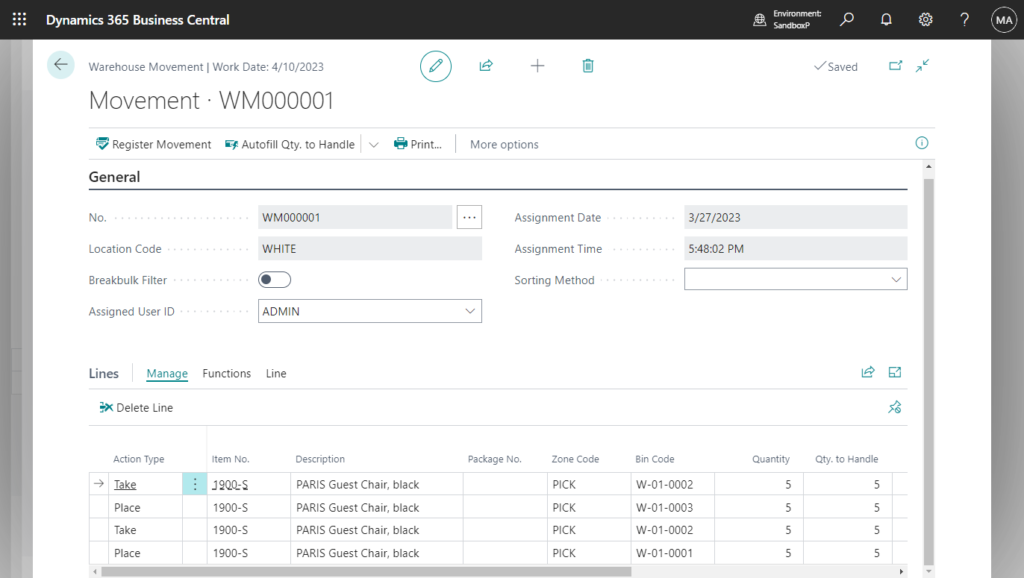

Routine movements are the movements you plan to replenish the bins with the fastest moving inventory. When you calculate bin replenishment, Business Central finds bins with a higher bin ranking that must be replenished from lower ranking bins and creates lines for the movements. You can decide to create movement instructions for all suggested replenishments, or you can delete some of the lines before you create instructions. You might do this if you know that your employees only have time to perform a limited number of movements before the warehouse closes for the day.

Calculate Bin Replenishment

Calculate the movement of items from bulk storage bins with lower bin rankings to bins with a high bin ranking in the picking areas.

More Details: Plan Warehouse Movements in Worksheets and Move items in Dynamics 365 Business Central

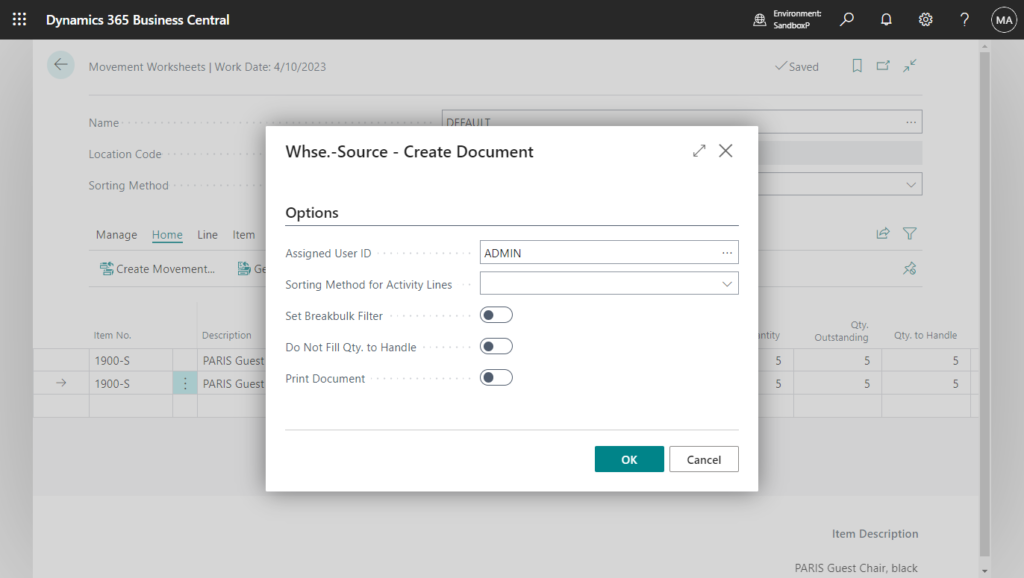

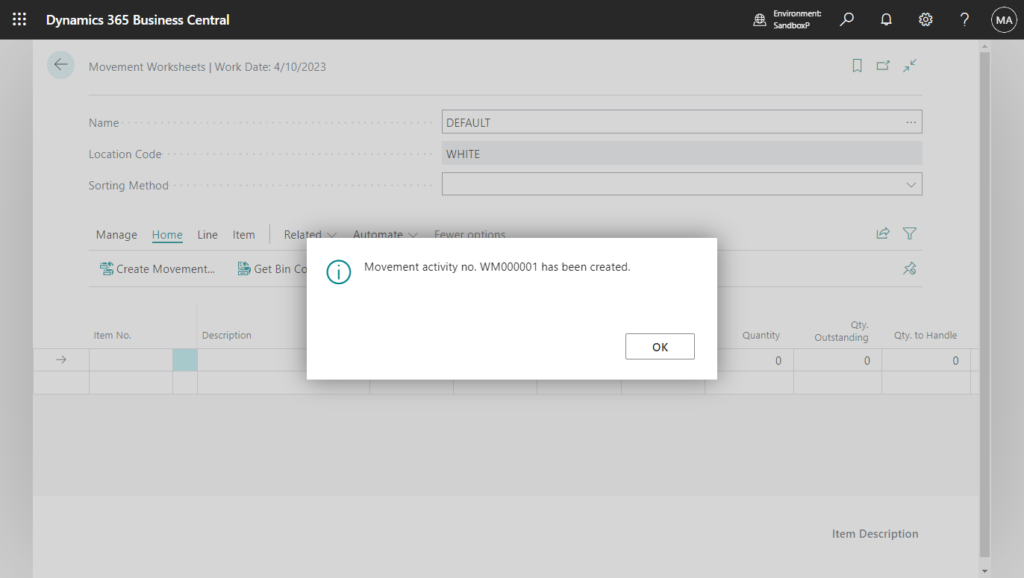

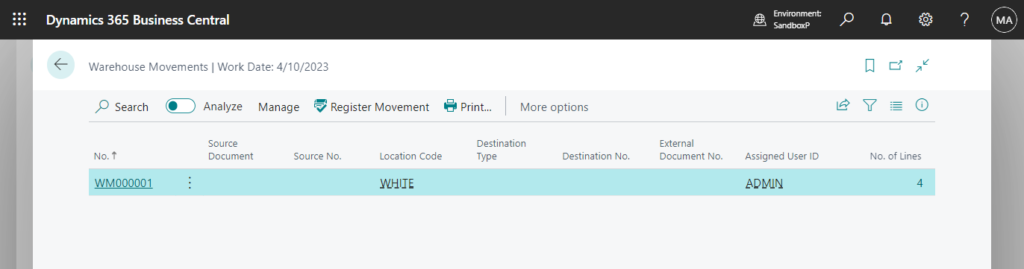

After you plan an inventory movement, or edit the suggested replenishments, you can create a movement to send the lines to a warehouse employee so they can take action. For directed put-away and pick locations, Business Central creates a Warehouse Movement document.

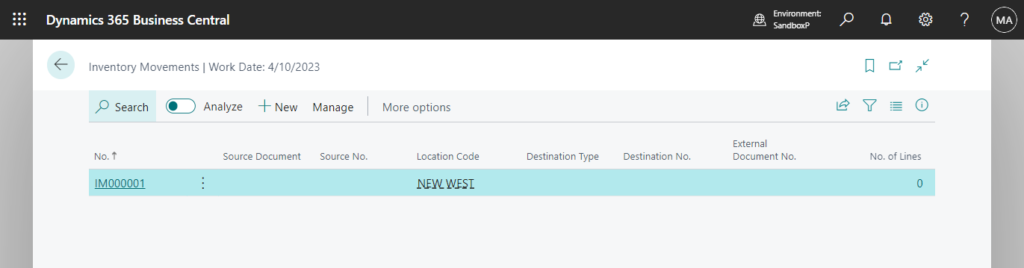

For others, Business Central creates Inventory Movement documents (which is new).

PS:

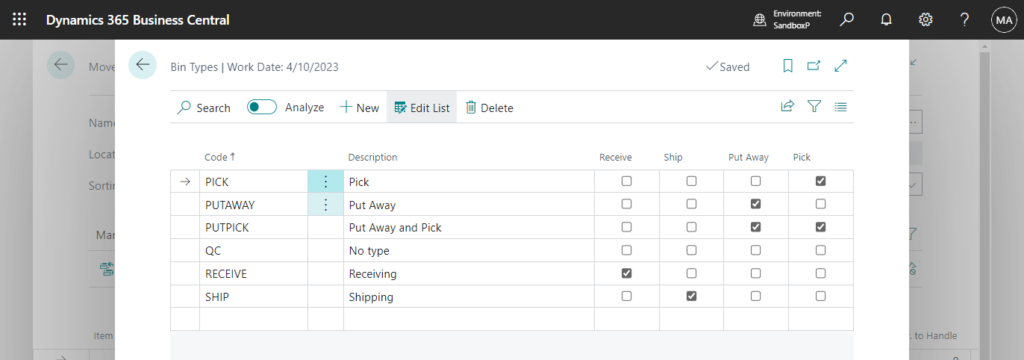

1. The bin types that you can create are listed below. More details: Set Up Bin Types

| Bin Type | Description |

|---|---|

| RECEIVE | Items registered as posted receipts but not yet put away. |

| SHIP | Items picked for warehouse shipment lines but not yet posted as shipped. |

| PUT AWAY | Typically, items to be stored in large units of measure but that you do not want to access for picking purposes. Because these bins are not used for picking, either for production orders or shipments, your use of a Put Away type bin might be limited, but this bin type could be useful if you have purchased a large quantity of items. Bins of this type should always have a low bin-ranking, so that when received items are put away, other higher-ranking PUTPICK bins fixed to the item are put away first. If you are using this type of bin, you must regularly perform bin replenishment so that the items stored in these bins are also available in PUTPICK or PICK type bins. |

| PICK | Items to be used only for picking, for example, for items with an approaching expiration date that you have moved into this type of bin. You would place a high bin ranking on these bins so they are suggested for picking first. |

| PUTPICK | Items in bins that are suggested for both the put-away and pick functions. Bins of this type probably have different bin rankings. You can set up your bulk storage bins as this type of bin with low bin rankings compared to your ordinary pick bins or forward picking area bins. |

| QC | This bin is used for inventory adjustments if you specify this bin on the location card in the Adjustment Bin Code field. You can also set up bins of this type for defective items and items being inspected. You can move items to this type of bin if you want to make them inaccessible to the usual item flow. NOTE: Unlike all other bin types, the QC bin type has none of the item handling check boxes selected by default. This indicates that any content you place in a QC bin is excluded from item flows. |

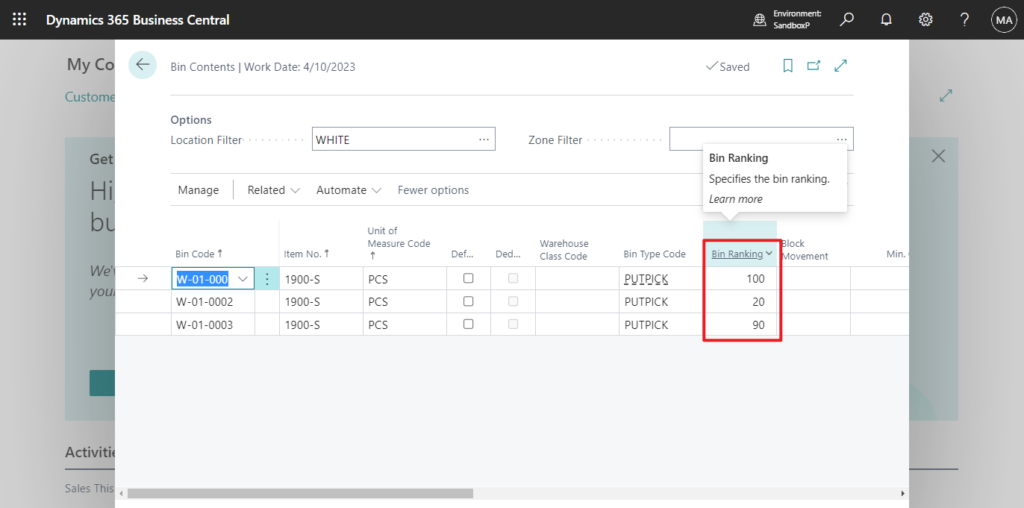

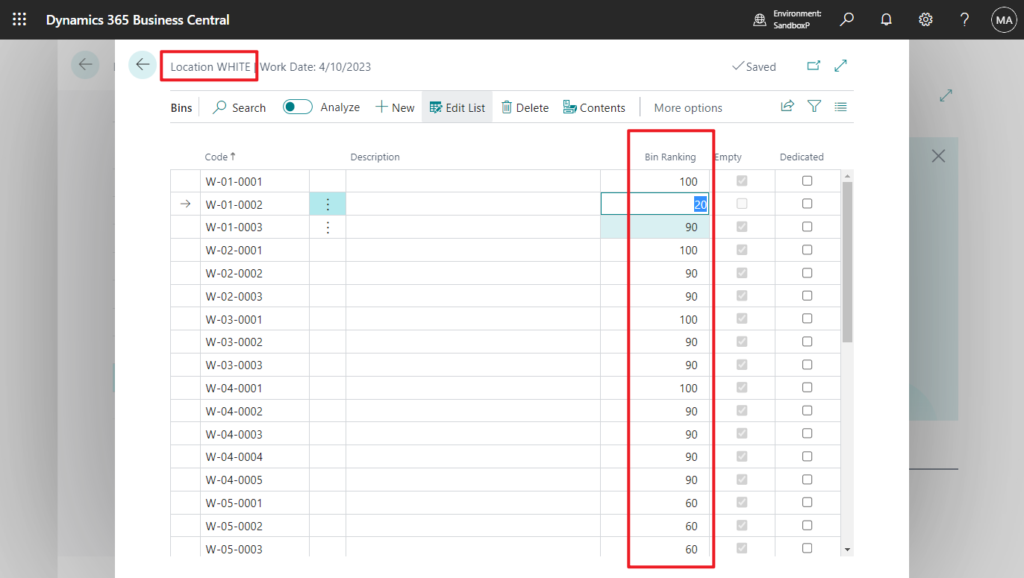

2. Bin Ranking: In advanced warehousing, you can automate and optimize how to collect items in put-away and pick worksheets by ranking bins. Items are suggested for picks and put-aways based on the bin ranks.

Put-away processes are optimized according to bin ranking by suggesting higher-ranking bins before lower-ranking bins. Pick processes suggest items with the highest bin ranking from bin content first. Bin replenishment suggests lower-ranking bins before higher-ranking bins.

Bin ranking and bin contents are the basic properties that guide warehouse employees in the warehouse.

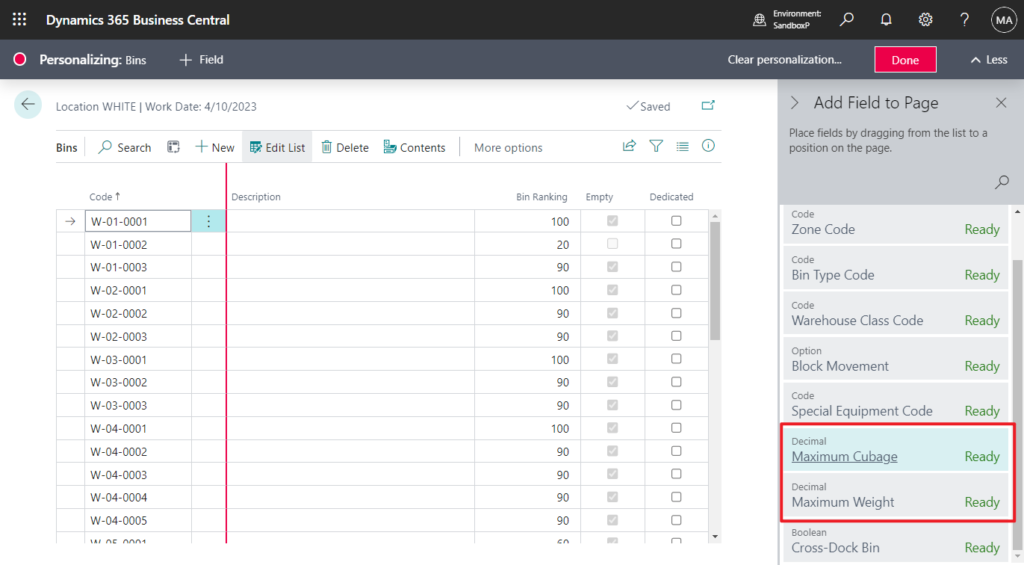

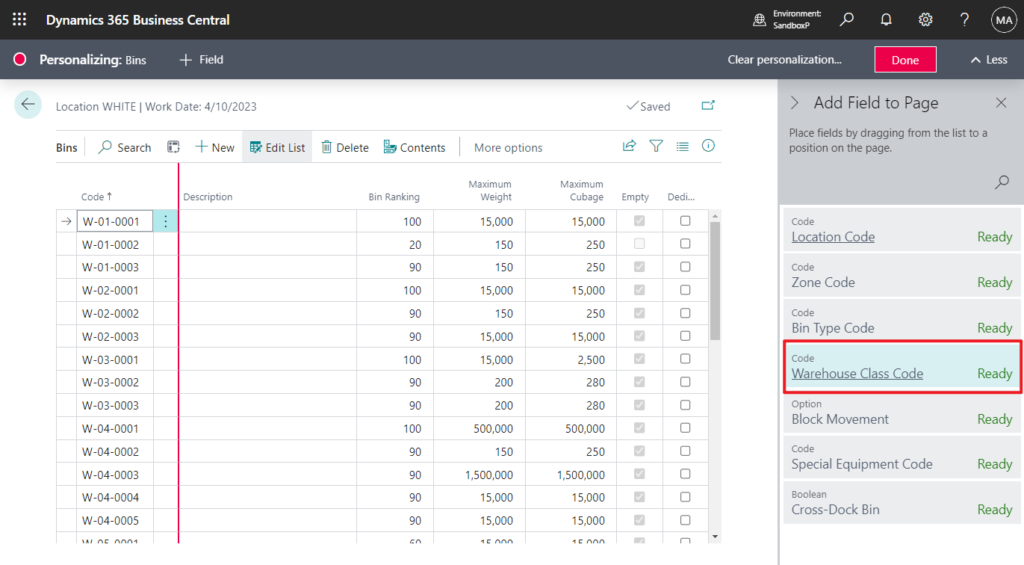

Bin Ranking can be set in Locations -> Bins, but it needs to be displayed on the page using the Personalize feature.

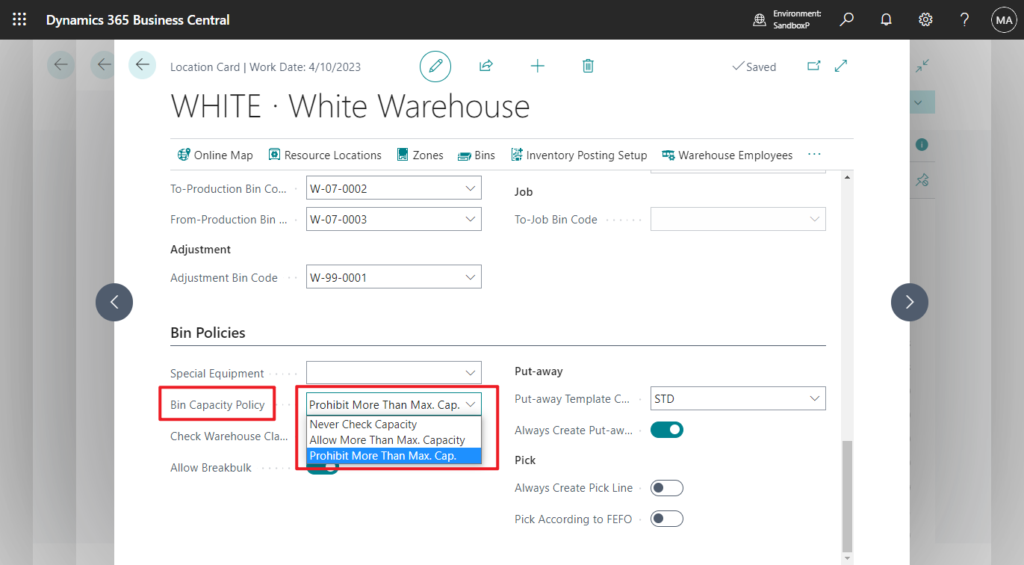

Bin Capacity Policy

Bin capacity policies define how Business Central handles bin capacity in cubage and weight.

Bin Capacity Policy

Specifies how bins are automatically filled, according to their capacity.

| Option | Description |

|---|---|

| Never Check Capacity | This is the default value for locations with bins where Directed Put-away and Pick isn’t enabled. This option is similar to the original behavior, where Business Central doesn’t check capacity. |

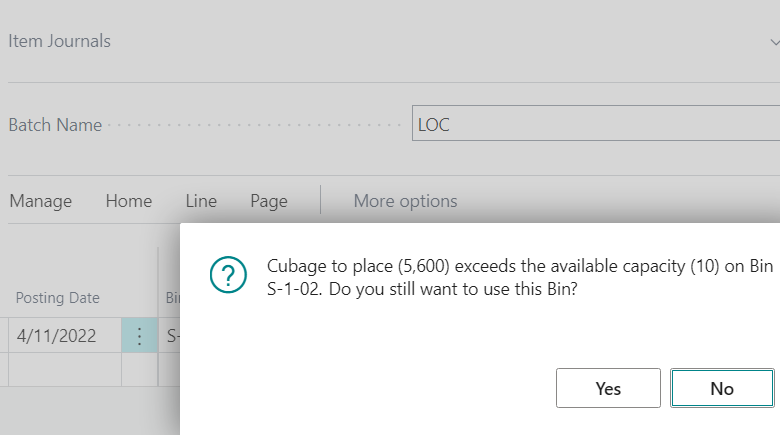

| Prohibit More Than Max. Cap. | If you select this option, a positive item journal, warehouse receipt, put-away, or incoming movement can’t be processed if the quantity exceeds the maximum capacity of the assigned bin. |

| Allow More Than Max. Capacity | Business Central shows warning but allows you to register the increase. |

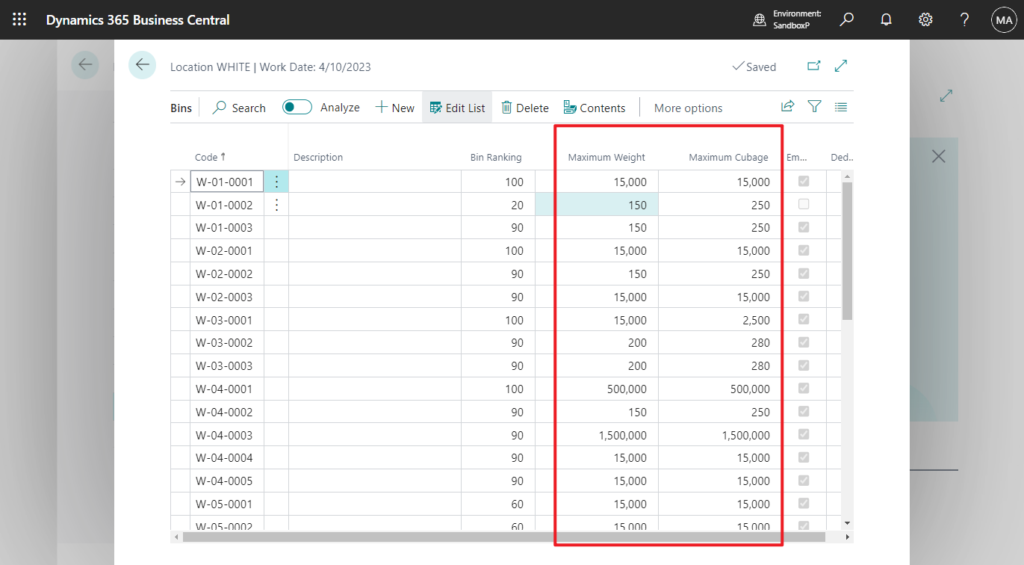

You can define the Max Cubage and Max weight on the bin.

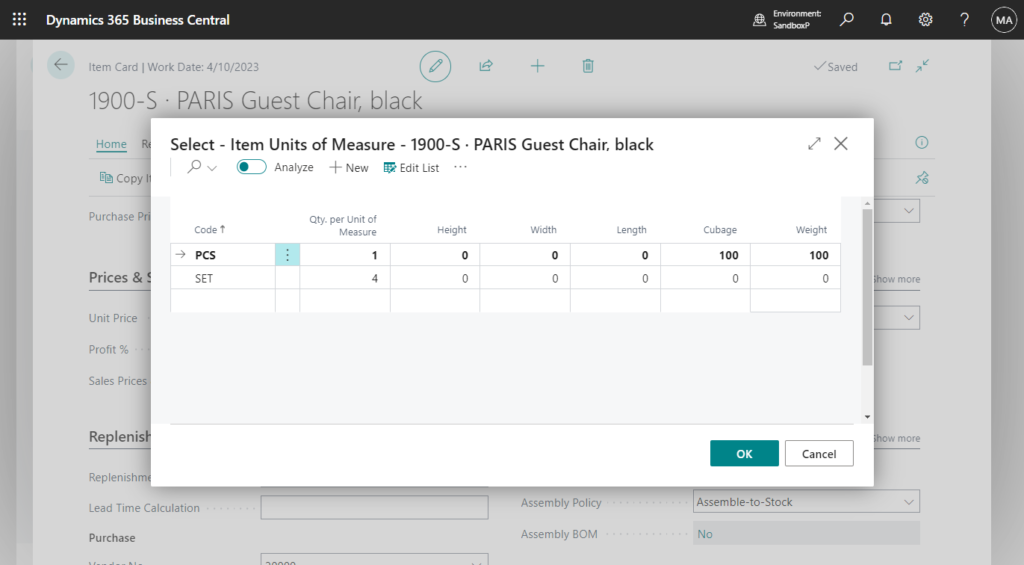

For item units of measure, Business Central calculates cubage based on the Length, Width, and Height fields, and the weight based on value in the Net Weight and Qty. per Unit of Measure fields on the Item Card page.

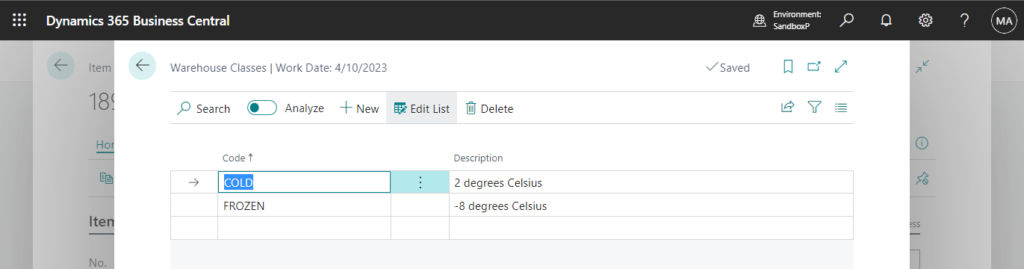

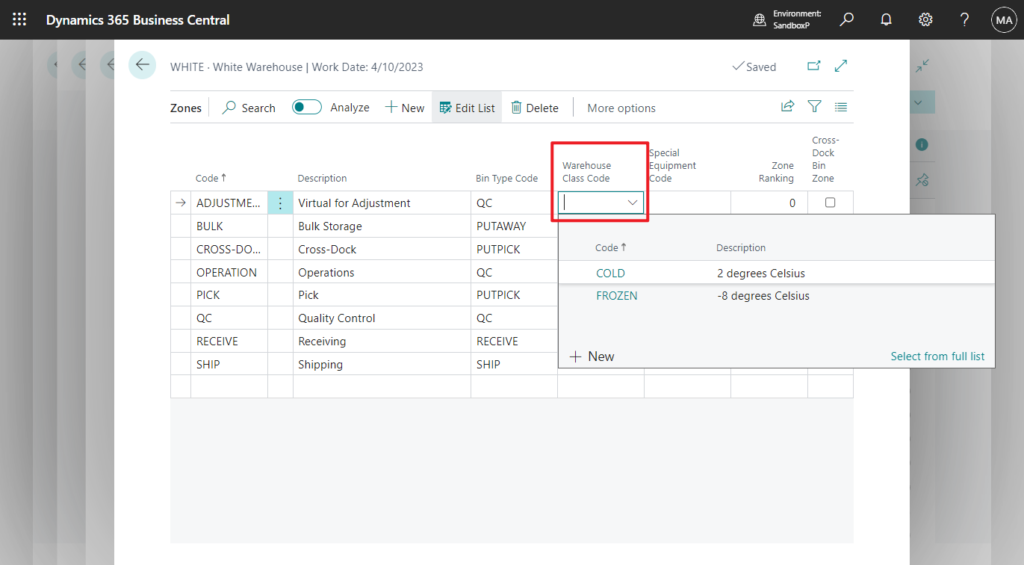

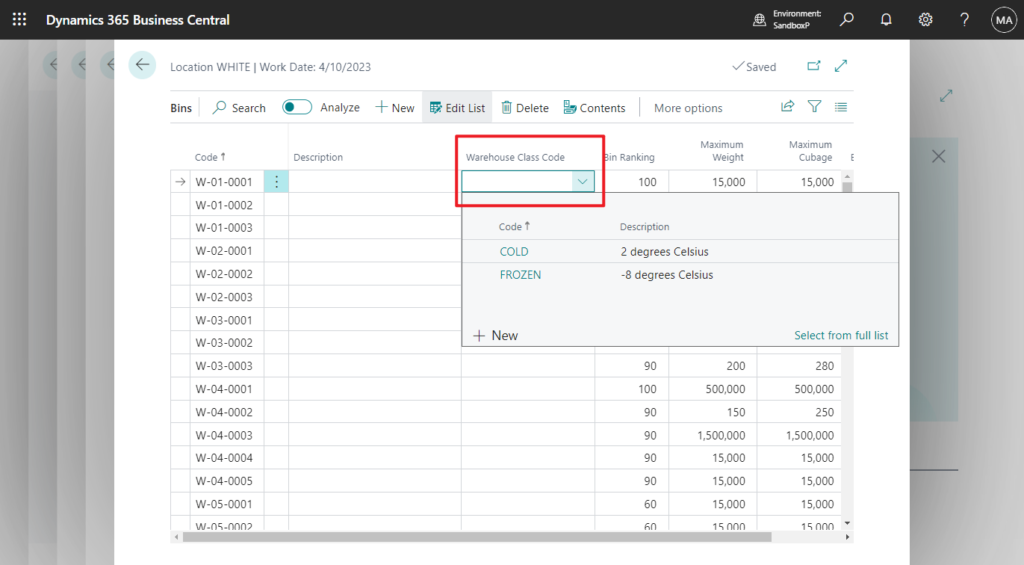

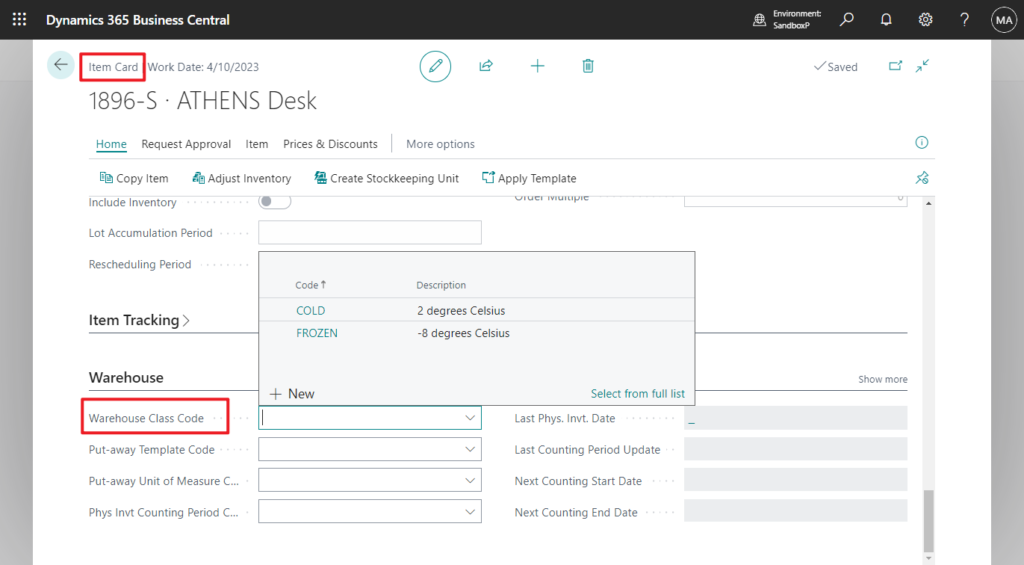

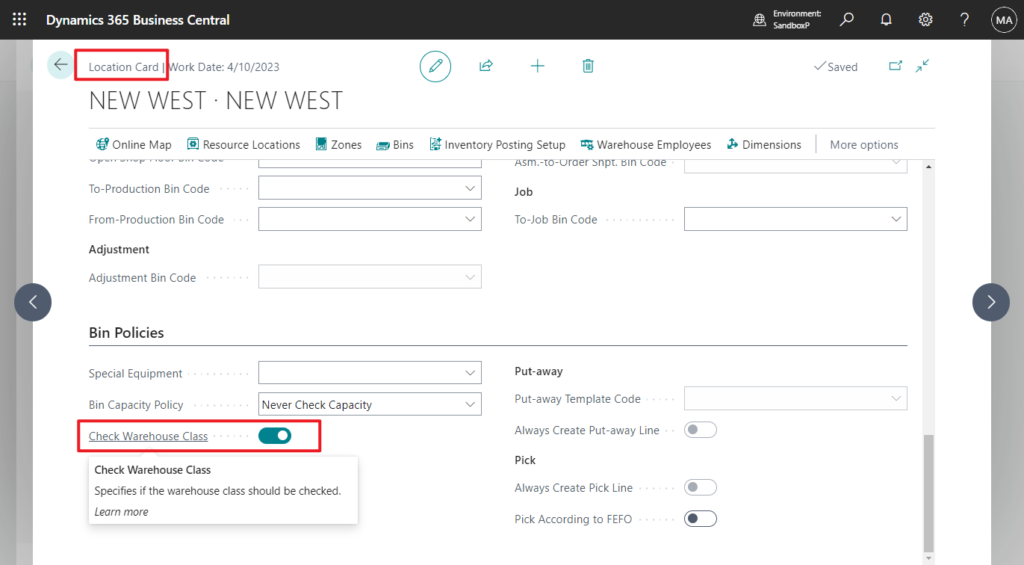

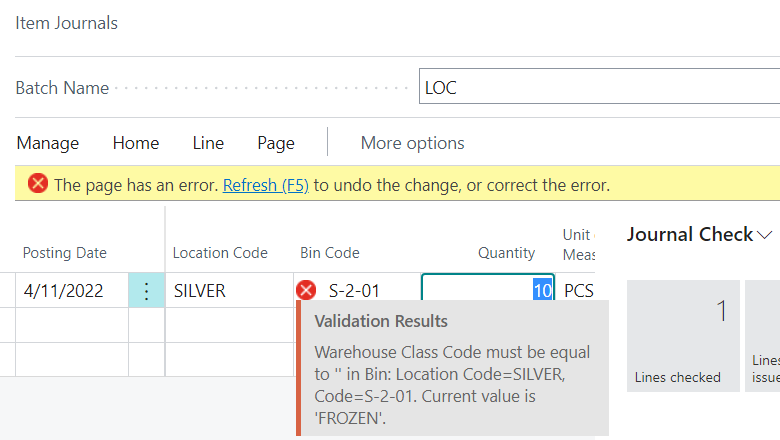

Warehouse class check

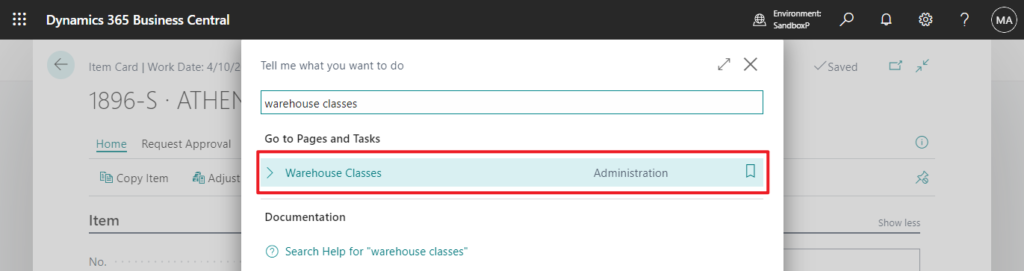

You can assign a warehouse class code to a zone, bin, or item.

Zone

Bin

Item

You can turn on the Check Warehouse Classes toggle on the Location Card page for any location that uses bins.

Business Central ensures that each item is stored only in bins that have the same warehouse class.

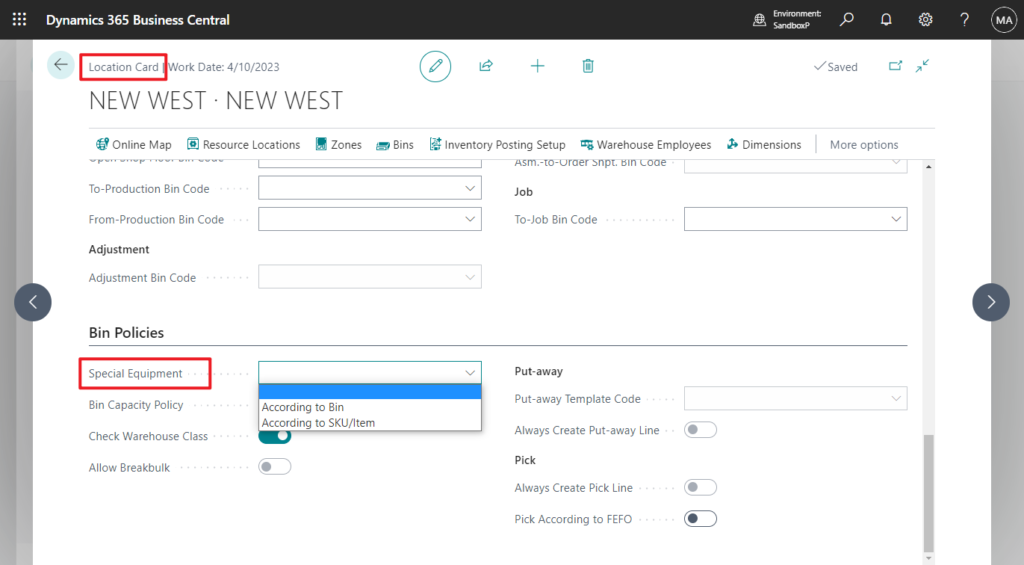

Special equipment in warehouse documents

For locations with bins, you can specify the equipment that you want employees to use when they work with a particular zone, bin, item, or SKU. In the Special Equipment field on the Location Card, choose where Business Central should look for special equipment to be used in warehouse activities such as warehouse put-aways, picks, or movements.

Special Equipment

Specifies where the program will first looks for special equipment designated for warehouse activities.

Warehouse setup

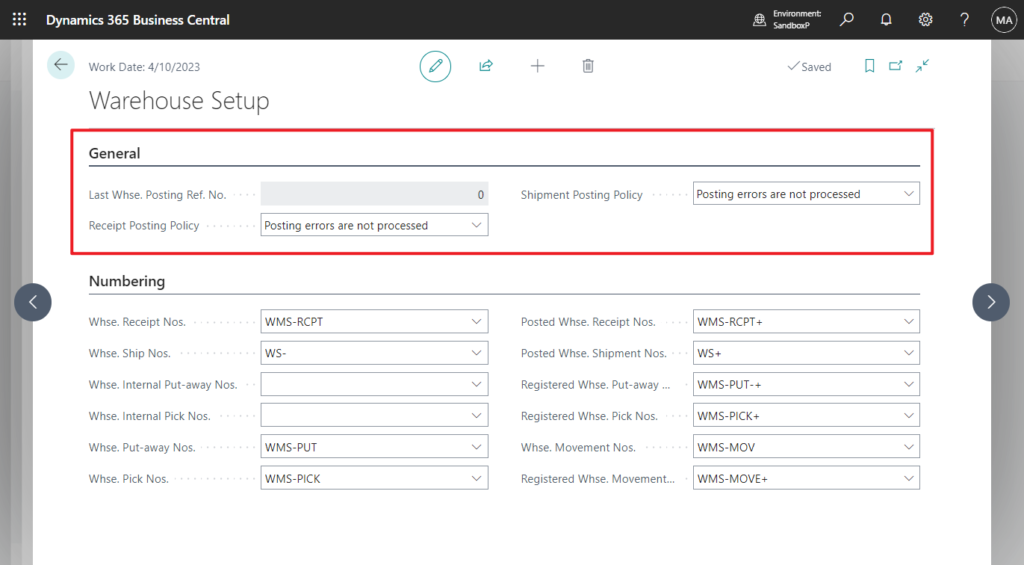

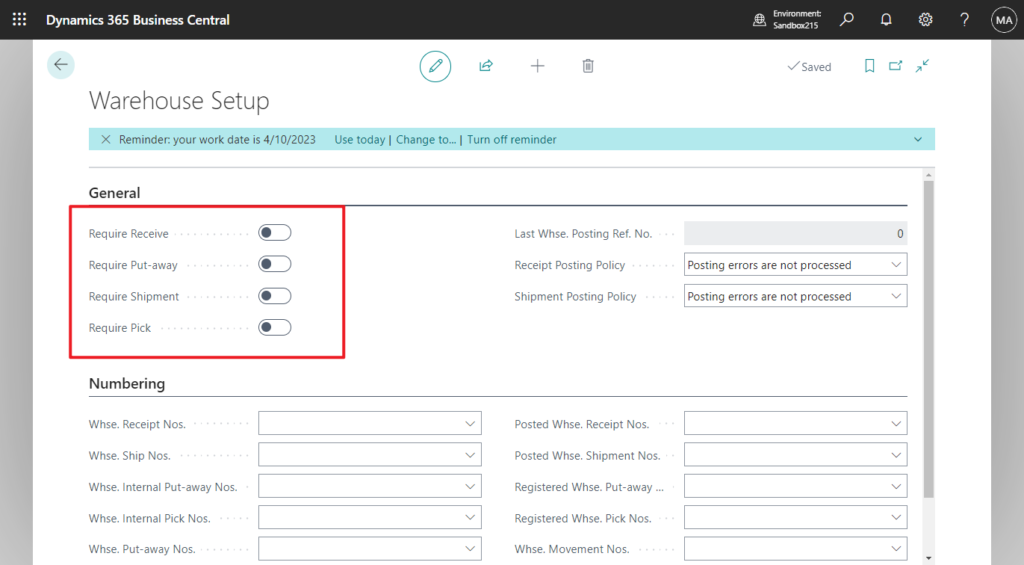

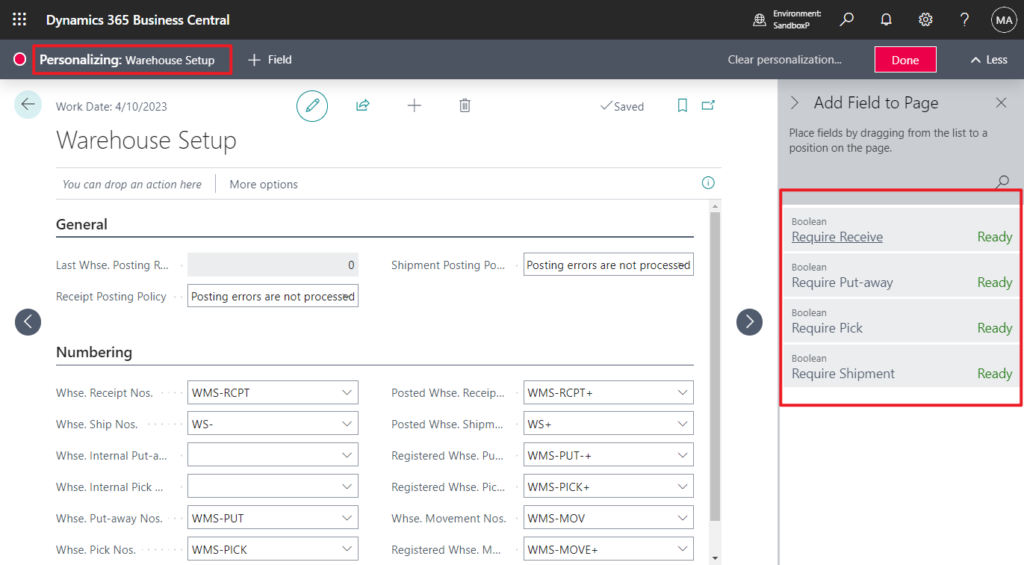

We gave the Warehouse Setup page a hidden improvement. The Require Shipment, Require Receipt, Require Pick, Require Put-away toggles are removed from the page, making sure the user focuses on the important fields. The fields allow warehouse handling with a blank location, which provides fewer capabilities and less flexibility compared to a normal location. They can also become a blocker if a company decides to use multiple locations. Our recommendation is to always use a location code.

https://learn.microsoft.com/en-us/dynamics365/release-plan/2023wave1/smb/dynamics365-business-central/use-advanced-warehouse-functionality-minimal-complexity#warehouse-setup

In BC 22.0:

In BC 21.5:

PS: The logic behind the fields is still in the product, so you can turn it back on. However, the fields will be removed in a future release.

END

Hope this will help.

Thanks for reading.

ZHU

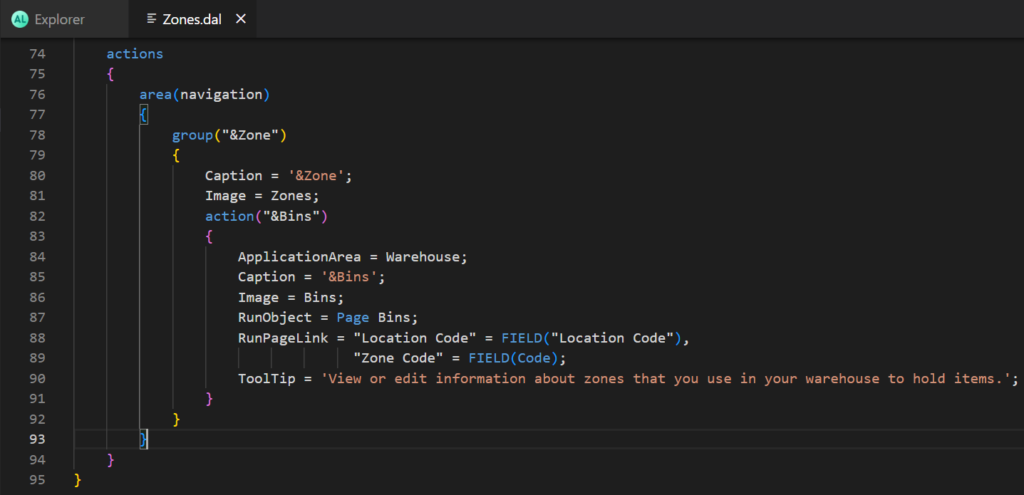

コメント