Hi, Readers.

The preview environment for Dynamics 365 Business Central 2022 release wave 1 (BC20) is available. Learn more: Link

I will continue to test and share some new features that I hope will be helpful.

Fixed Quantity in product bills of materials:

Business value:

You can ensure that the consumption of a component is the same, regardless of the scrap or output quantities.

Feature details:

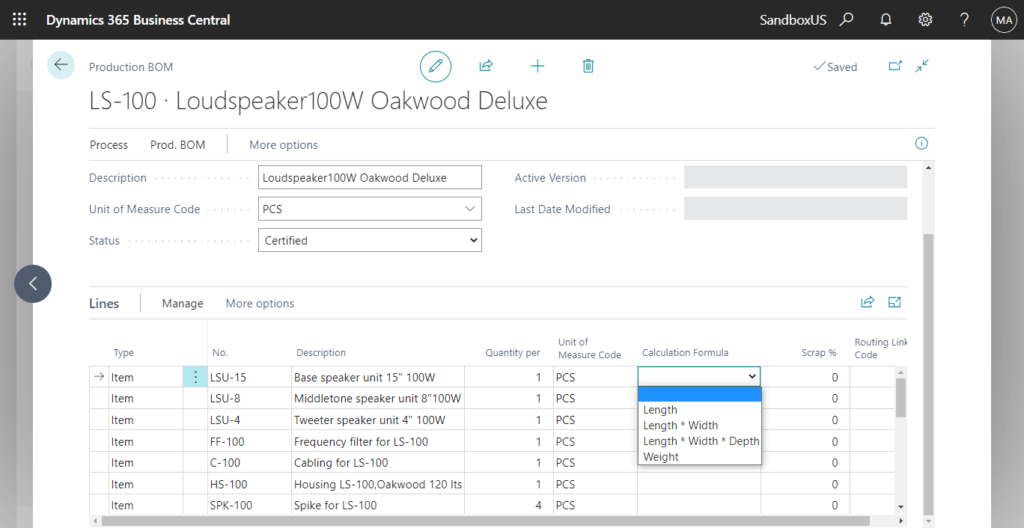

You can select the Fixed Quantity option in the Calculation Formula field on production BOM lines, planning components, and production order components to ensure that the consumption of a component is the same.

https://docs.microsoft.com/en-us/dynamics365-release-plan/2022wave1/smb/dynamics365-business-central/fixed-quantity-product-bills-materials

This is a small update for manufacturing.

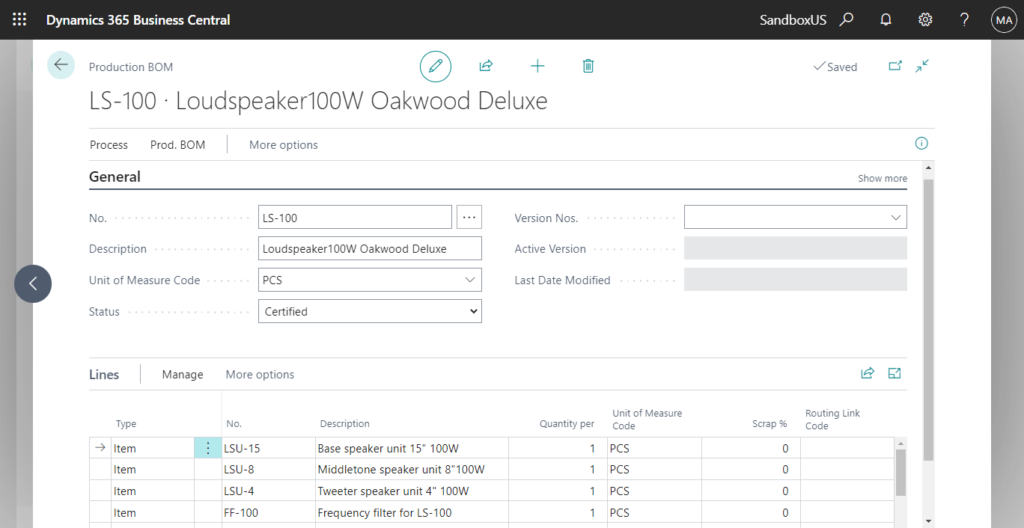

A production bill of material (BOM) holds master data that describes the components and subassemblies used in the production of a parent item. Once a production order is created for that parent item, its production BOM will govern the calculation of material requirements as represented on the Prod. Order Components page.

The quantity is calculated taking into consideration different dimensions which are also entered on the production BOM lines. The dimensions refer to an order unit of the respective item. The length, width, depth and weight can be entered as dimensions.

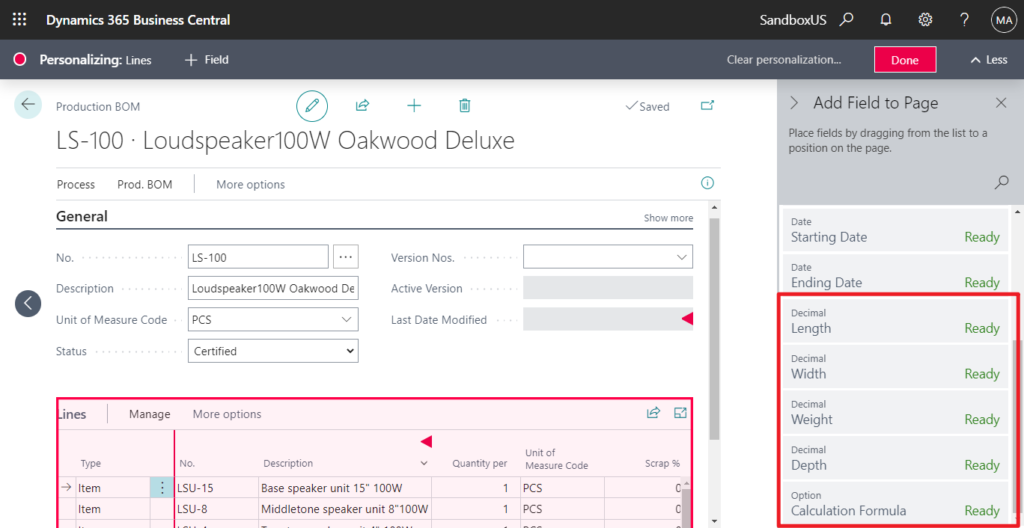

The Calculation Formula, Length, Width, Depth and Weight columns are not displayed, because they are only used by some users. If you wish to use the calculation of the quantity, you must first display these columns.

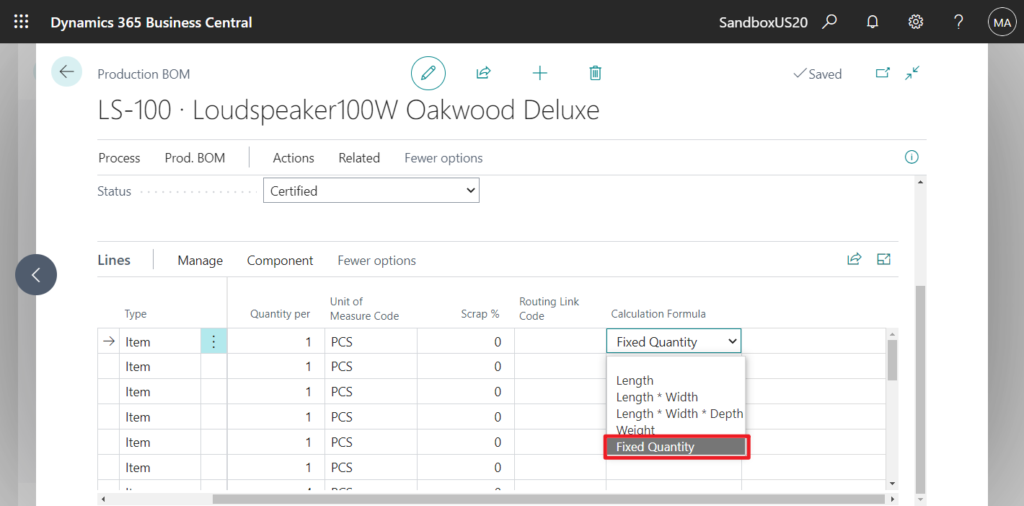

Now, you can select the Fixed Quantity option in the Calculation Formula field.

PS: in BC19.5

So you can choose from the following values in the Calculation Formula field now:

- Blank: The quantity is not calculated.

- Length: Quantity = Length * Quantity per

- Length * Width: Quantity = Length * Width * Quantity per

- Length * Width * Depth: Quantity = Length * Width * Height * Quantity per

- Weight: Quantity = Weight * Quantity per

- Fixed Quantity = Quantity Per

Let’s see more details.

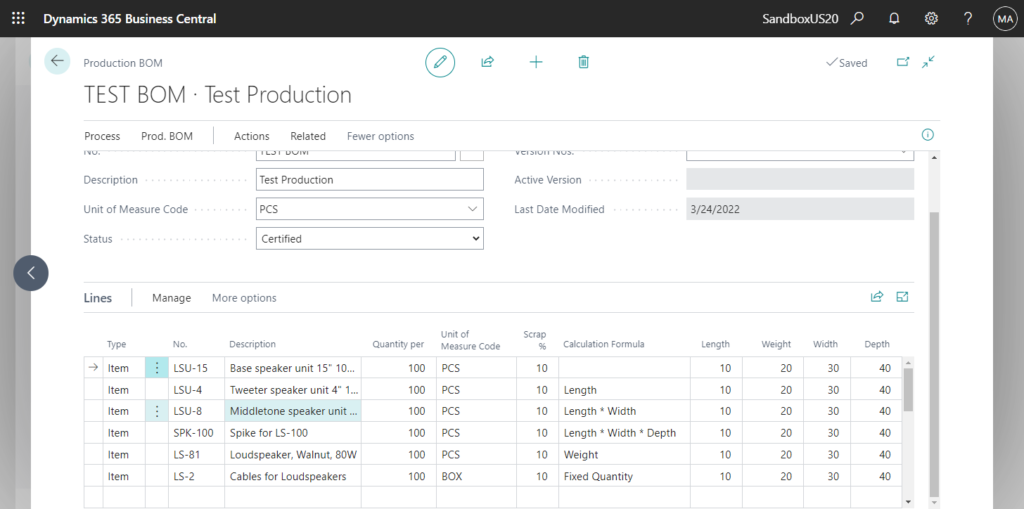

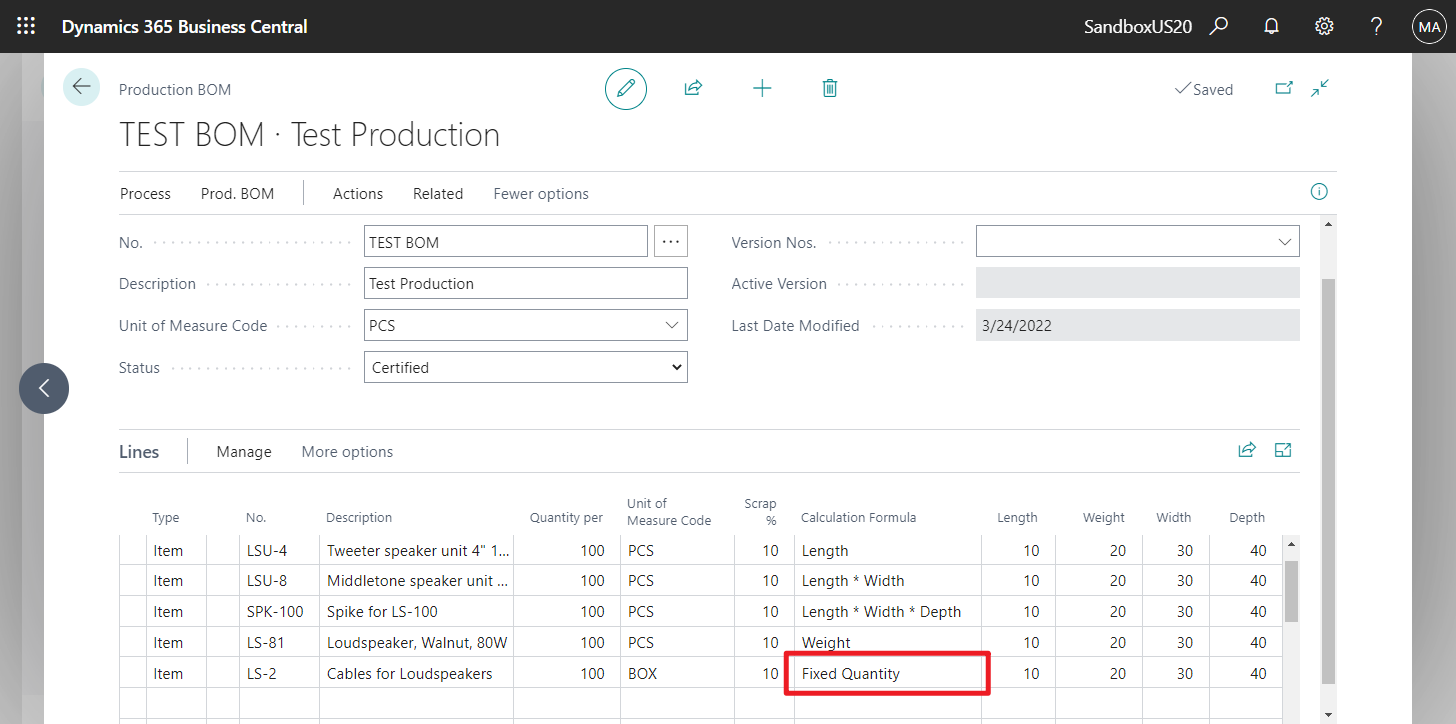

First, I created a test Production Bom using six different Calculation Formulas. Other conditions are the same.

Quantity Per: 100

Scrap%: 10

Length: 10

Weight: 20

Width: 30

Depth: 40

| Type | No. | Description | Quantity per | Unit of Measure Code | Scrap % | Calculation Formula | Length | Weight | Width | Depth |

|---|---|---|---|---|---|---|---|---|---|---|

| Item | LSU-15 | Base speaker unit 15″ 100W | 100 | PCS | 10 | 10 | 20 | 30 | 40 | |

| Item | LSU-4 | Tweeter speaker unit 4″ 100W | 100 | PCS | 10 | Length | 10 | 20 | 30 | 40 |

| Item | LSU-8 | Middletone speaker unit 8″100W | 100 | PCS | 10 | Length * Width | 10 | 20 | 30 | 40 |

| Item | SPK-100 | Spike for LS-100 | 100 | PCS | 10 | Length * Width * Depth | 10 | 20 | 30 | 40 |

| Item | LS-81 | Loudspeaker, Walnut, 80W | 100 | PCS | 10 | Weight | 10 | 20 | 30 | 40 |

| Item | LS-2 | Cables for Loudspeakers | 100 | BOX | 10 | Fixed Quantity | 10 | 20 | 30 | 40 |

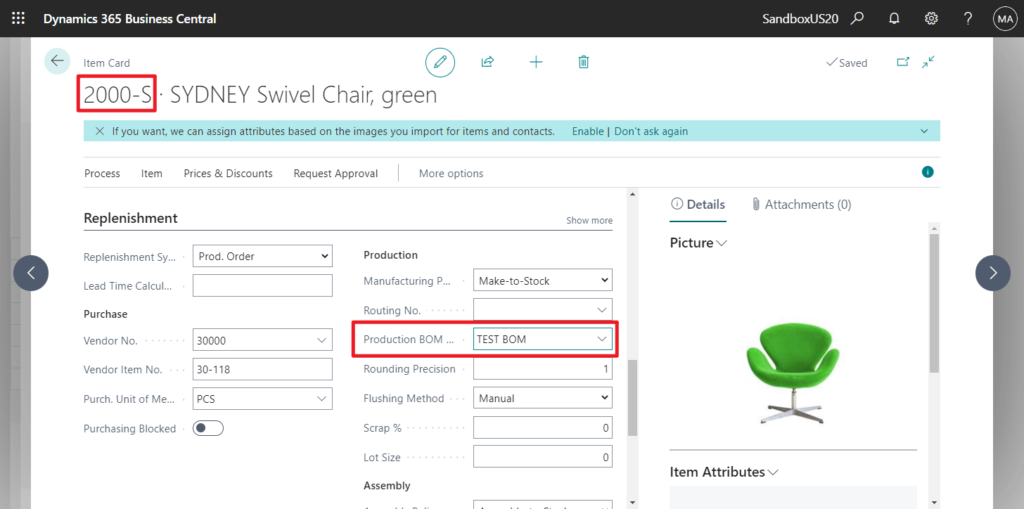

Assign the test bom to item 2000-S.

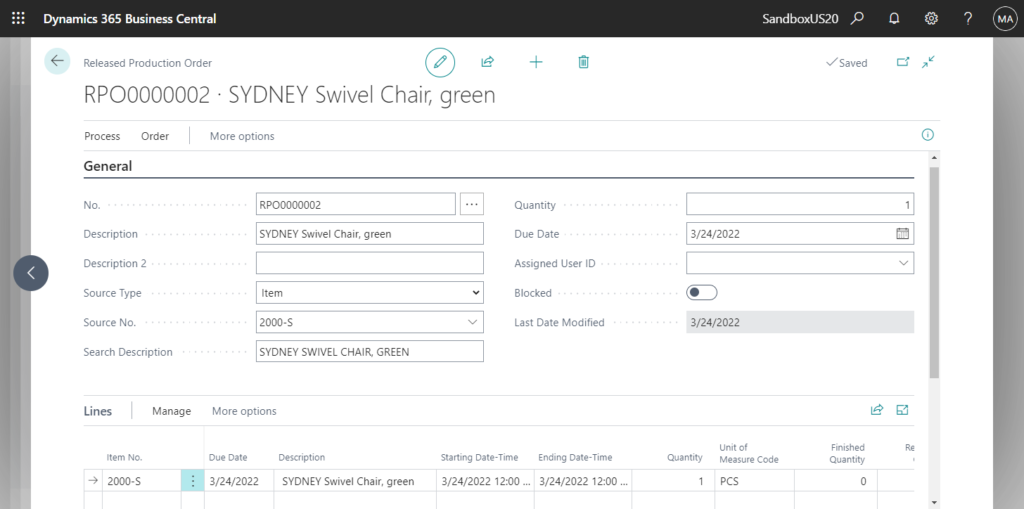

Then create a new Production Order and change status to Released.

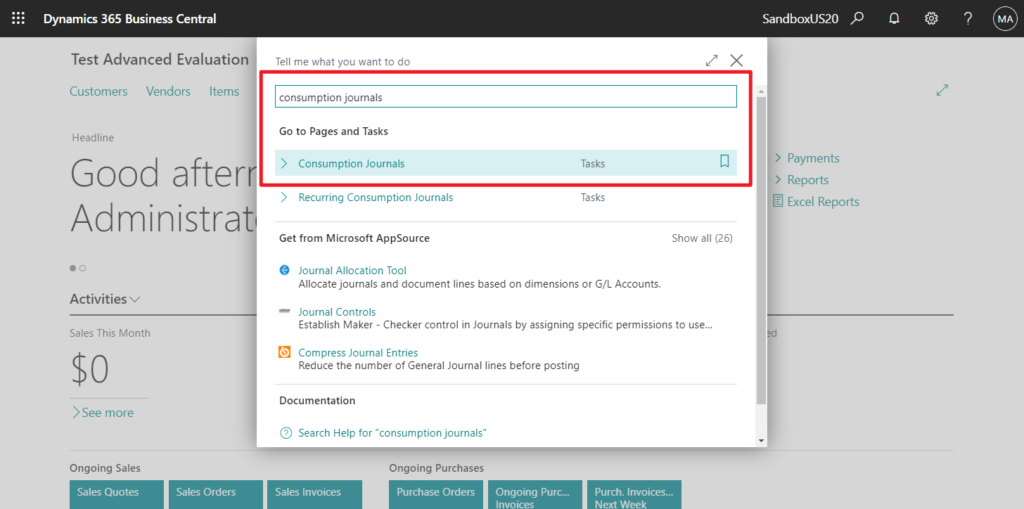

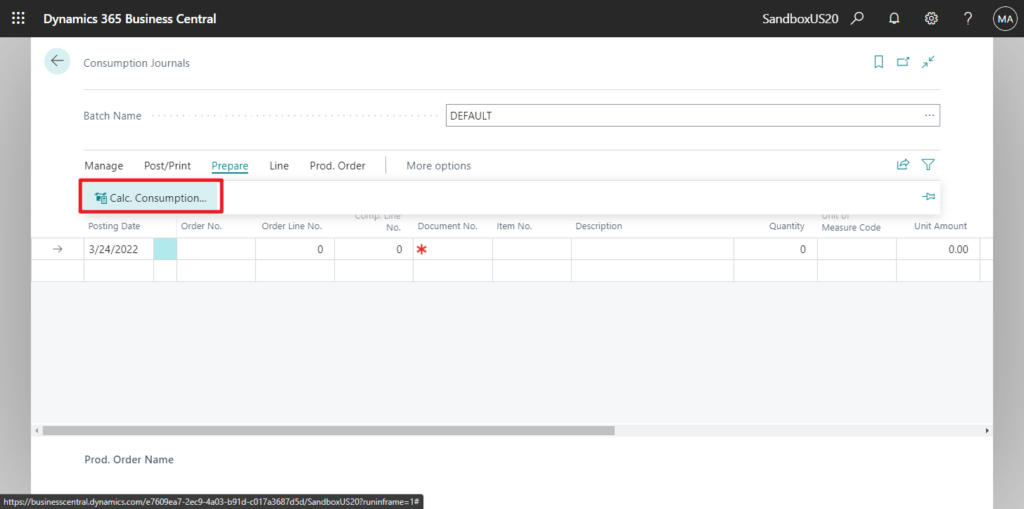

Open Consumption Journals page.

Choose Calc. Consumption…

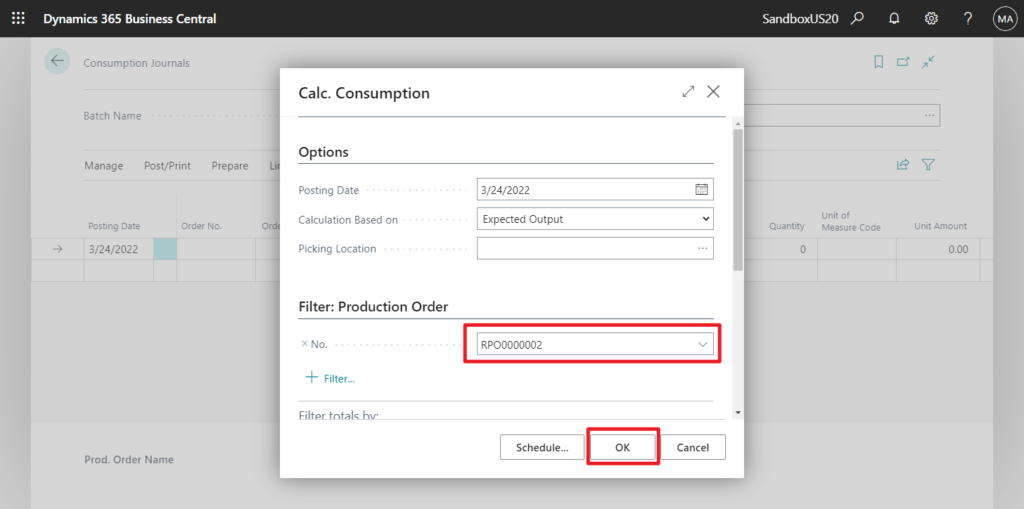

Select the released production order number.

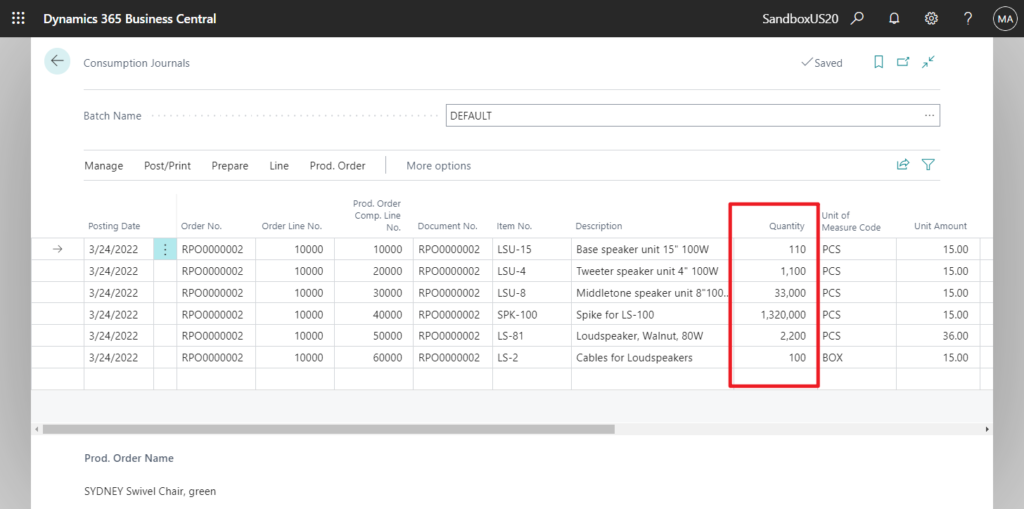

The calculation result of material requirements is as follows.

| Posting Date | Order No. | Order Line No. | Prod. Order Comp. Line No. | Document No. | Item No. | Description | Quantity | Unit of Measure Code |

| 3/24/2022 | RPO0000002 | 10000 | 10000 | RPO0000002 | LSU-15 | Base speaker unit 15″ 100W | 110 | PCS |

| 3/24/2022 | RPO0000002 | 10000 | 20000 | RPO0000002 | LSU-4 | Tweeter speaker unit 4″ 100W | 1,100 | PCS |

| 3/24/2022 | RPO0000002 | 10000 | 30000 | RPO0000002 | LSU-8 | Middletone speaker unit 8″100W | 33,000 | PCS |

| 3/24/2022 | RPO0000002 | 10000 | 40000 | RPO0000002 | SPK-100 | Spike for LS-100 | 1,320,000 | PCS |

| 3/24/2022 | RPO0000002 | 10000 | 50000 | RPO0000002 | LS-81 | Loudspeaker, Walnut, 80W | 2,200 | PCS |

| 3/24/2022 | RPO0000002 | 10000 | 60000 | RPO0000002 | LS-2 | Cables for Loudspeakers | 100 | BOX |

In production order components, when the Calculation Formula field is set to Fixed Quantity, the Expected Quantity field value is always equal to the Quantity Per field. The scrap % that is defined on the same line is ignored. Fixed quantity is respected by the Availability by BOM report that will show the item as the bottleneck if the available quantity is less than the quantity in the Quantity Per Parent field. The Able to Make Parent and Able to Make Top Item fields always have blank values regardless of the available quantity. Fixed quantity is respected by the Standard Cost Calculation process. Lot size for the produced item impacts the cost allocated for one item.

Fixed Quantity in product bills of materials – Dynamics 365 Release Plan | Microsoft Docs

END

Hope this will help.

Thanks for reading.

ZHU

コメント